Production of bicycles

The bicycle developing and manufacturing process includes several stages, which we want to tell you about

How do we create

our bikes?

VNC has been developing and manufacturing bicycles since 2006, and during this time has come a long way in improving the technological solutions used in the manufacture of each bicycle of the brand. The whole process of development and creation of a bicycle takes about 18 months, including all stages, starting with planning a model range and ending with the completion of production of each individual bicycle.

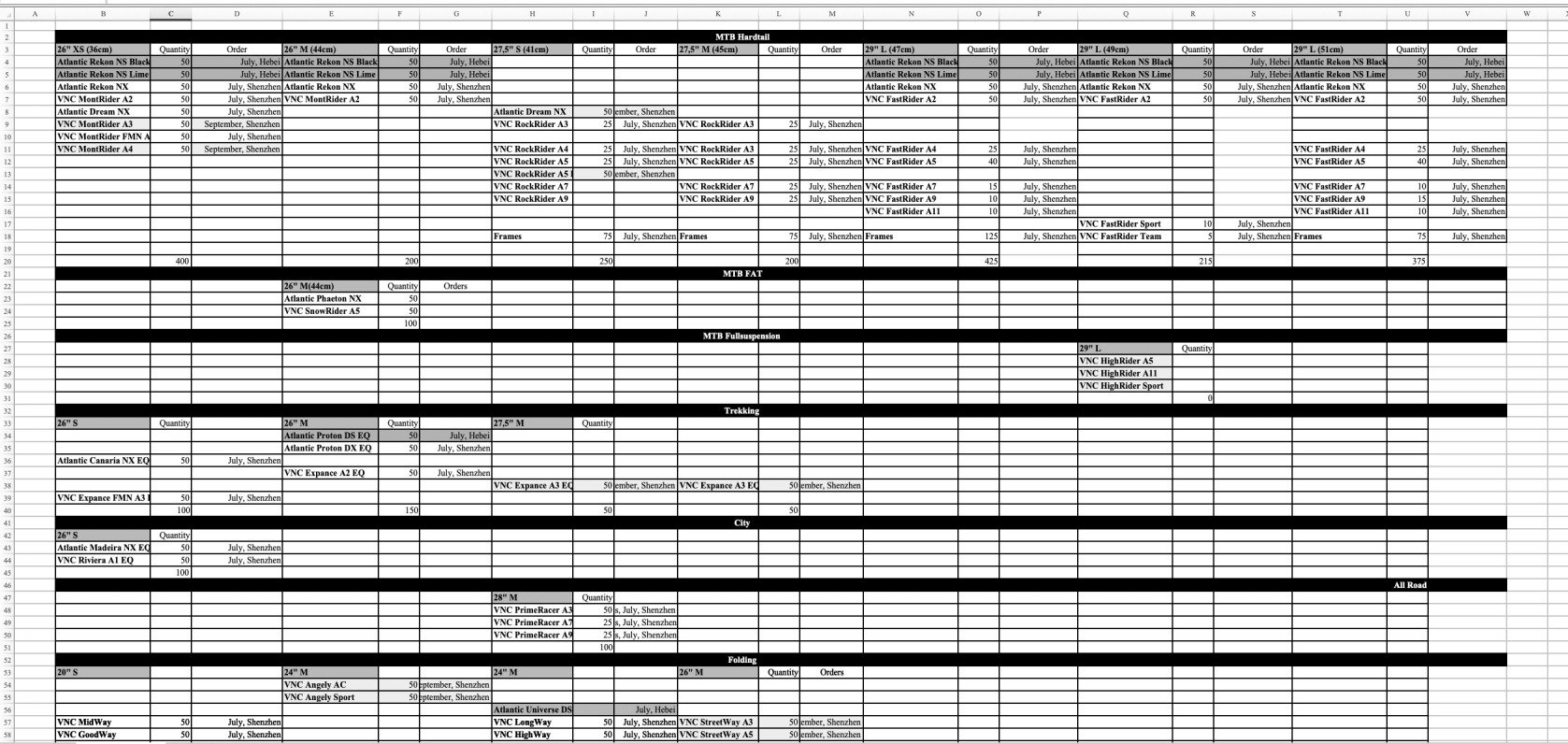

So, the first step in building bicycles is to strategically plan for the VNC range for the year ahead. It is in this plan that the main trends in the development of the market, the specifics of the demand of potential buyers are taken into account and potential new models are preliminarily thought out that will be able to fulfill customer requests.

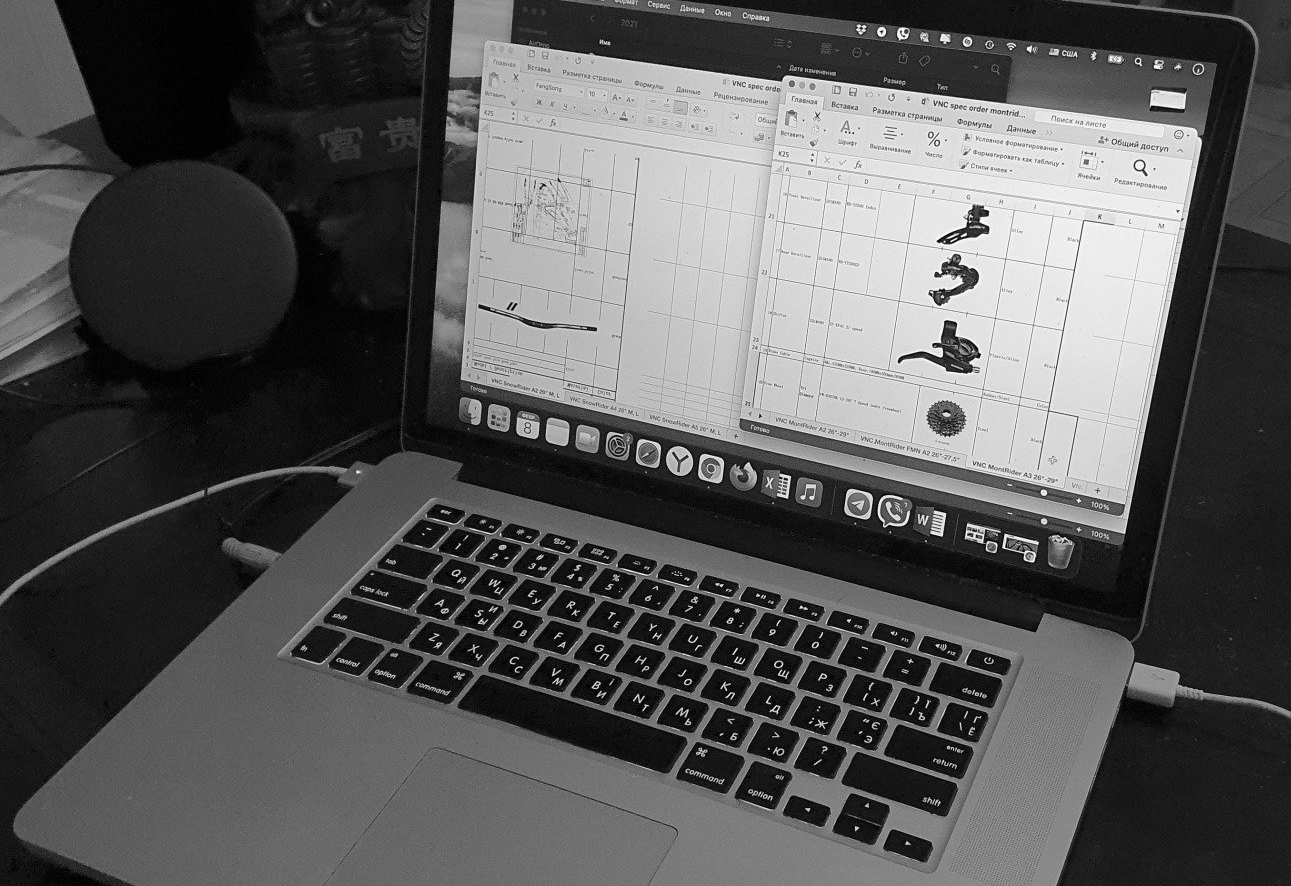

The next step in the process of creating a bicycle is the preliminary development of its technical specification, which includes the selection of components from which the bicycle will be assembled. As a rule, VNC uses a significant part of its own V-Class components in production, as well as components from well-known manufacturers with a good reputation in the market, including Shimano and Microshift shifting systems, suspension forks and other components from SR Suntour, cranks and other components. from Prowheel, saddle from Velo, brake systems from Tekto and Logan, and tires from Maxxis, ChaoYang, Compass and Wanda.

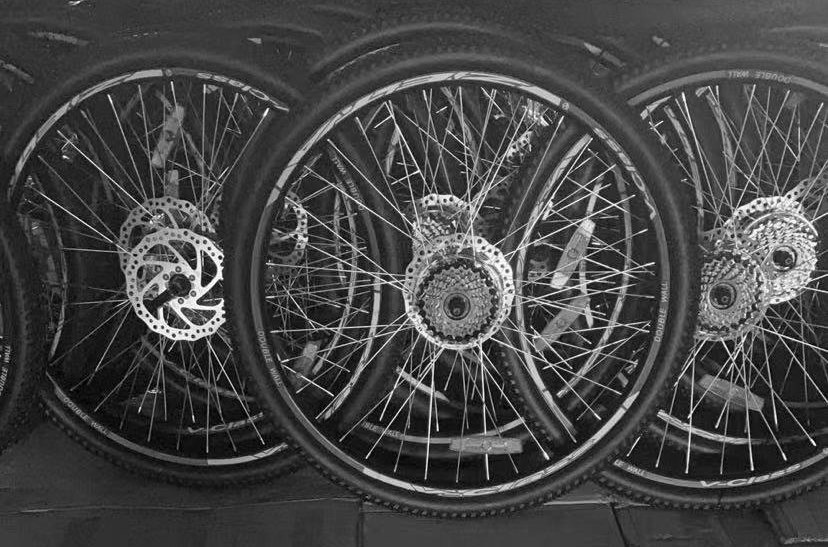

The fourth stage is a logical continuation of the previous stage. It includes the production of components in a limited amount, their delivery to the factory, where ready-made test samples of bicycles are collected from them and tested. Upon successful completion of the testing process, each VNC bike model moves on to the next stage of mass production. If necessary, additional changes and improvements are made to the bicycle specification.

The fifth stage is the direct transportation of all the necessary components in full to the production factories, where VNC bicycles are massively assembled and configured from them. After passing this stage, the bicycles are completely ready and further transported to the places of their sale on the market.

After passing all the above stages, bicycles are sent to their dealers and distributors in all countries, where they find their happy buyers and delight them with their excellent technical capabilities at a reasonable price.